Reduce frustration of clips falling off or spearing edge of sheet.

H clips required roof sheathing.

Installation details shall conform to sections 2304 7 1 and 2304 7 2 for floor and roof sheathing respectively.

H clips do not prevent wooden panels from buckling or warping.

Maximum 19 percent moisture content.

Not always required but a good idea.

H clips provide additional stiffness between bearing points for the unsupported edges of wood panel plywood or osb roof sheathing along with the necessary 1 8 gap for expansion as shown below illustrated on a bag of simpson h clips.

Roof sheathing comes in grid marked 4 by 8 foot sheets and should be installed perpendicular to the frame.

Some older h clips do not provide a built in gap.

8d ring shank nails should be used instead.

H clips for roof sheathing.

They are often used with roof sheathing to keep it from feeling spongy or soft at its edges.

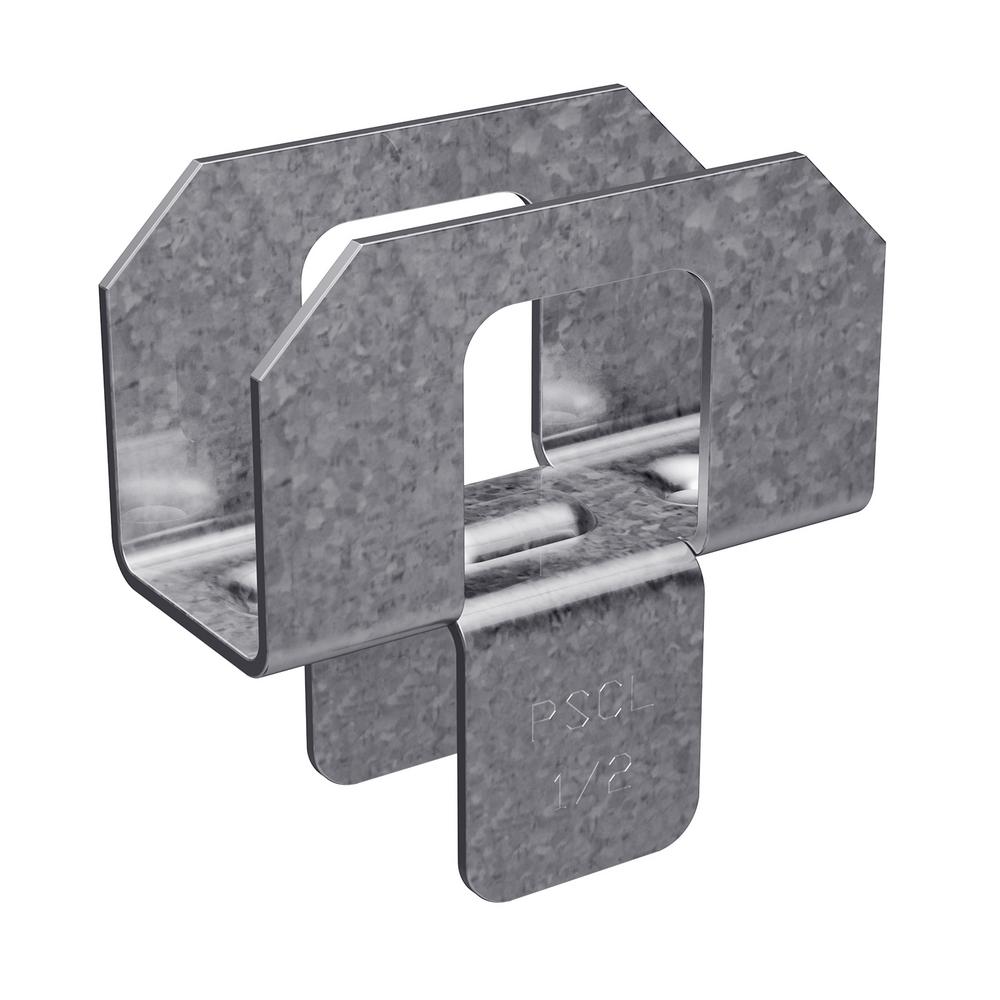

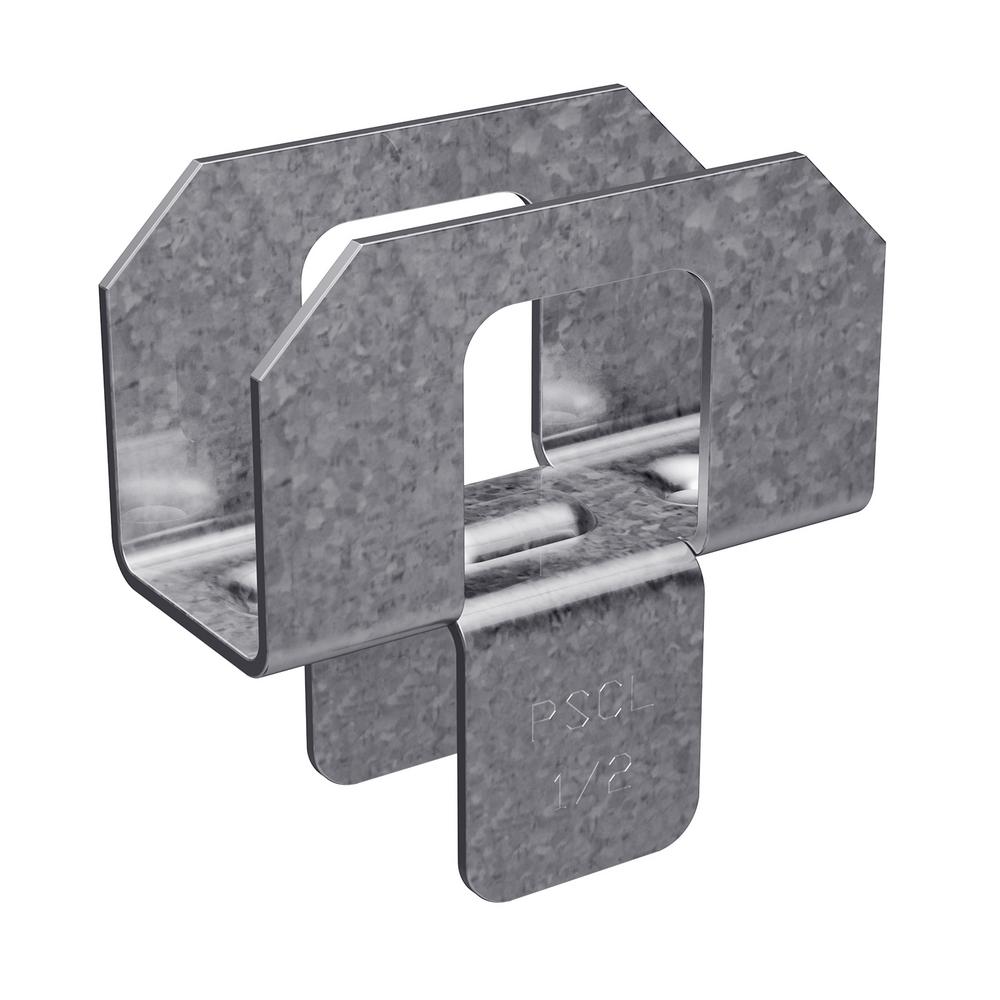

H clips also called panel edge clips are small steel devices that fit snugly between wood panels in order to provide them with edge support.

Their size should match the thickness of the panels to which they are attached.

In either case the cost of the job is reduced.

Full length expansion bar gives you superior alignment and perfect expansion gap.

Grip h clips are designed to make installing roof sheathing faster with better spacing.

Floor or roof sheathing conforming with this table shall be deemed to meet the design criteria of section 2304 7.

The typical thickness range for sheathing is 3 8 to 3 4 inch.

H clips may also allow builders to use thinner sheathing than they otherwise would be permitted to use.

Table 2304 7 2 sheathing lumber minimum grade requirements.